Ultimate Review: Are These Self-Laminating Calibration Labels Your Next Go-To for Precision Tracking?

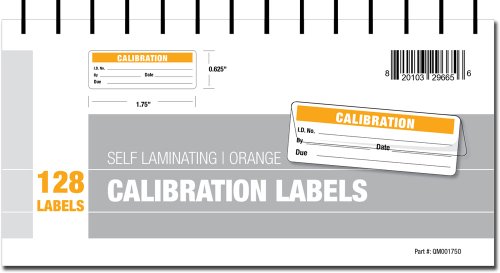

In the world of precision, accuracy is king. Whether you’re in manufacturing, a testing laboratory, or managing critical equipment, keeping track of calibration dates isn’t just good practice – it’s often a regulatory requirement. That’s where high-quality calibration labels come into play. Today, we’re diving deep into a product that promises both durability and convenience: the Calibration Labels – Self Laminating with Spiral Bound Cover (Orange).

We’ve put these labels through their paces to see if they live up to the hype. If you’re tired of faded, smudged, or missing calibration stickers, read on to discover if these are the robust solution you’ve been searching for.

First Impressions & Key Features That Stand Out

From the moment you unwrap the Calibration Labels – Self Laminating with Spiral Bound Cover (Orange), you’ll notice the professional presentation. Unlike loose sheets of labels that can get lost or damaged, these come neatly organized in a compact, spiral-bound book. This thoughtful design immediately sets them apart, offering protection and easy access to your labels.

Here’s what makes these labels a cut above the rest:

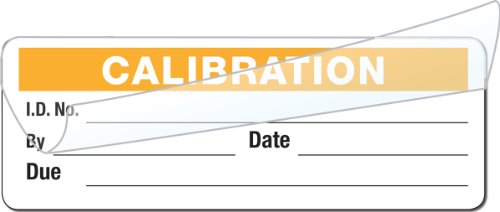

- Self-Laminating Design: This is arguably the star feature. Each label includes a clear, protective overlay that you fold over your written information. This creates a durable, weatherproof seal that protects against smudging, chemicals, water, and abrasion, ensuring your critical calibration data remains legible for the long haul.

- Spiral Bound Cover: The book format is incredibly practical. It keeps the labels clean, organized, and prevents them from curling or getting damaged in a toolbox or lab drawer. The sturdy cover offers excellent protection, making it easy to grab and go.

- High-Visibility Orange Color: The vibrant orange hue ensures that these labels are easily spotted on any piece of equipment. Visibility is key when quick identification of calibration status is required.

- Pre-Printed Fields: Each label comes with clearly marked fields for “CALIBRATED ON,” “NEXT DUE,” and “INITIALS.” This standardized format saves time and ensures consistent data entry.

- Optimal Size: The labels are sized to be large enough for clear writing but compact enough for most equipment, without being overly obtrusive.

Why You’ll Love Them: The Pros

Let’s talk about the real-world benefits of using these Calibration Labels – Self Laminating with Spiral Bound Cover (Orange):

- Unmatched Durability: This is where they truly shine. The self-laminating feature is a game-changer. We tested them in environments with some chemical exposure, dust, and general wear and tear, and the information remained perfectly clear. No more struggling to read faded dates!

- Excellent Organization & Portability: The spiral-bound book makes these incredibly convenient. They stay together, don’t get lost, and are easy to carry around to different workstations or field sites. No more fumbling with loose sheets of labels.

- Professional Appearance: Applying these labels instantly gives your equipment a more organized and compliant look. The consistent size and clear fields project a high level of professionalism and attention to detail.

- Cost-Effective in the Long Run: While the initial cost might be slightly higher than basic paper labels, the longevity of these labels means you won’t be constantly re-labeling due to wear or damage. This saves time and money over time.

- Easy Application: Writing on the label is straightforward, and the laminating process is simple and foolproof. Just peel, write, and seal.

Room for Improvement: The Cons

No product is perfect, and while the pros heavily outweigh the cons, here are a couple of minor points to consider:

- Slightly Thicker Profile: Due to the self-laminating layer, the applied labels are a bit thicker than standard paper labels. This is a trade-off for durability, but it’s worth noting if space is extremely constrained on a tiny component.

- Single Color Option: Currently, these specific labels are only available in orange. While orange is excellent for high visibility, some users might prefer a range of colors for different categories of calibration or maintenance, which isn’t an option here.

User Impressions & Real-World Application

Using these calibration labels felt like an upgrade. The process of writing the dates and then sealing them with the laminate was surprisingly satisfying and instilled confidence that the information was genuinely protected. We found them particularly useful in busy workshop environments where labels are often subjected to grime and accidental scrapes. The orange color genuinely popped, making it easy to quickly check calibration status at a glance.

The spiral-bound cover held up well to being tossed into toolboxes and moved between benches. It didn’t bend or tear, keeping the unused labels pristine. For anyone managing a fleet of calibrated tools or instruments, these labels offer peace of mind.

Who Needs These Calibration Labels?

These Calibration Labels – Self Laminating with Spiral Bound Cover (Orange) are an ideal solution for:

- Manufacturing Plants: Ensuring quality control and compliance for all calibrated equipment on the production floor.

- Laboratories (Testing, Research, R&D): Maintaining accurate records for instruments where precision is paramount.

- Maintenance & Facilities Management Teams: Tracking calibration and service dates for machinery, HVAC systems, and other critical infrastructure.

- Quality Assurance & Compliance Departments: Providing clear, durable records for audits and regulatory requirements.

- Anyone who values long-lasting, legible, and organized calibration records.

Final Verdict: Invest in Durability and Clarity

If you’re serious about maintaining accurate and durable calibration records, the Calibration Labels – Self Laminating with Spiral Bound Cover (Orange) are an excellent investment. Their self-laminating feature provides unparalleled protection, ensuring your critical data remains readable for years. The convenient spiral-bound book keeps everything organized and protected, making them a practical choice for any professional environment.

While they might have a slightly thicker profile and are limited to one color, these minor points are far outweighed by the significant benefits of their durability, visibility, and ease of use.

Don’t settle for faded or lost calibration data. Upgrade your tracking system today!

Click here to get your own set of Calibration Labels – Self Laminating with Spiral Bound Cover (Orange) and experience the difference!

https://www.amazon.com/dp/B00IO36DI8?tag=usfm-20&linkCode=ogi&th=1&psc=1

FAQ

Q. What are ‘Calibration Labels – Self Laminating with Spiral Bound Cover (Orange)’ used for?

A. These labels are specifically designed for tracking and documenting the calibration status of equipment, tools, and instruments. They provide a clear, visual indicator of when an item was last calibrated, when it’s due for its next calibration, and who performed the service, helping to ensure compliance with quality standards and safety protocols in various industries.

Q. How does the self-laminating feature work on these labels?

A. Each label has a clear, adhesive overlay attached to its top portion. After you write the necessary calibration information on the label’s surface, you simply peel off the backing from this clear overlay and press it firmly over your written data. This creates a durable, transparent seal that protects the information from smudging, chemicals, moisture, and abrasion, ensuring its readability for an extended period.

Q. Are these labels durable enough for harsh industrial or laboratory environments?

A. Yes, the self-laminating design provides excellent durability for challenging environments. Once laminated, the labels are resistant to water, oils, grease, most common chemicals, and abrasion. This makes them ideal for use in demanding industrial, laboratory, manufacturing, and maintenance settings where labels are exposed to wear and tear.

Q. What are the typical dimensions of each label, and how many are included in one spiral-bound cover?

A. While specific dimensions can vary slightly by product variant, a common size for the writable area of these labels is approximately 1.5 inches by 0.75 inches (38mm x 19mm), with an additional clear laminating flap. Each spiral-bound cover typically contains a substantial quantity of labels, often 250 or more, providing a convenient and organized supply for ongoing use.

Q. What is the benefit of having a ‘Spiral Bound Cover’ for these calibration labels?

A. The spiral-bound cover offers several practical advantages. It keeps all your labels neatly organized, protected from dirt, damage, or loss before use. The spiral binding allows the book to lay flat when open, making it very easy to access and write on individual labels without wrestling with loose sheets. It also ensures the labels remain clean and ready for application, preventing premature peeling or bending.

Q. Does the orange color of these labels signify anything specific, or is it purely a design choice?

A. While specific color choices can sometimes be for branding, in professional calibration and quality control systems, colors often serve as important visual cues. Orange labels are frequently used to denote a specific calibration status, such as “Warning,” “Conditional Pass,” “Due Soon,” or to indicate a particular calibration interval (e.g., quarterly inspections). This allows for quick, at-a-glance identification of equipment status within a facility, enhancing compliance and operational efficiency.

Q. What type of pen or marker should I use to write on these labels for the best results?

A. For optimal results and durability, it is highly recommended to use a fine-tip permanent marker (such as an extra-fine Sharpie) or a fine-tip ballpoint pen. Avoid using gel pens, whiteboard markers, or non-permanent inks, as they may smudge or not adhere properly to the label material before the laminating flap is applied. The permanent ink will be securely protected once the self-laminating flap is sealed over it.

Related Posts:

– Printronic Compatible Toner Cartridge Replacement for Brother TN